Self-Clinching Nuts

A Self Clinching Nut, also known as a press-in nut, is a fastener designed to provide strong and permanent internal threads in thin sheet metal. By applying axial pressure during installation, the nut becomes mechanically locked into the base material, offering excellent resistance to rotation and push-out without the need for welding or tapping.

Self clinching nuts are widely used in sheet metal assemblies where material thickness is limited and conventional threading methods are not suitable. Once installed, the nut forms a flush surface on one side of the panel while delivering reliable threaded performance on the other.

Product Description

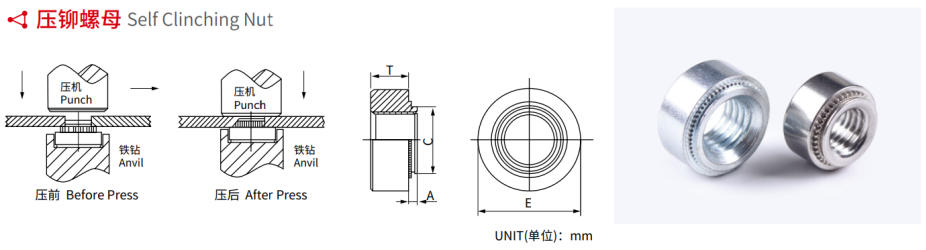

Dimensional Diagram & Parameters of Self-Clinching Nut

The dimensional diagram of the Self Clinching Nut illustrates both the pressing process and the key structural dimensions that ensure reliable clinching performance.

During installation, the nut is pressed into a pre-punched mounting hole using a punch and an anvil. Under pressure, the sheet metal flows into the undercut and serrated ring of the nut body, creating a permanent mechanical interlock.

Main dimensional parameters include:

- A – Clinching depth/nut height

- C – Head diameter

- E – Mounting hole diameter

- T – Overall thickness

All dimensions are measured in millimeters (mm). Proper matching of mounting hole size and plate thickness is essential to achieve optimal torque and push-out resistance.

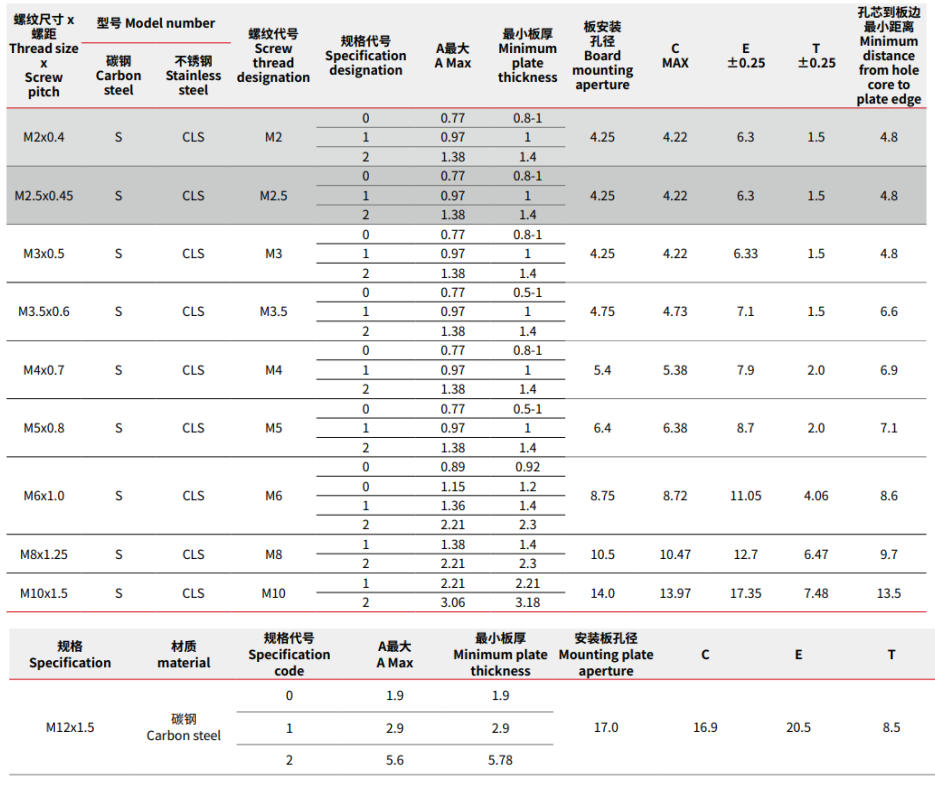

Specification of Self-Clinching Nut

Xinchi provides a complete range of Self Clinching Nuts with standard metric threads and multiple material options, suitable for different sheet metal thicknesses and application environments.

Thread sizes available:

M2 × 0.4, M2.5 × 0.45, M3 × 0.5, M3.5 × 0.6, M4 × 0.7,

M5 × 0.8, M6 × 1.0, M8 × 1.25, M10 × 1.5, M12 × 1.5

Material options:

- Carbon steel

- Stainless steel

- Hardened stainless steel

Each thread size is available with different specification codes (0 / 1 / 2), corresponding to different minimum plate thicknesses, mounting hole diameters, and overall dimensions, ensuring stable installation and consistent fastening performance.

Packaging & Shipping:

- Packaging: Plastic woven bags or customized according to customer requirements

- Shipping Method: LCL (Less than Container Load) or FCL (Full Container Load), packed with pallets

- Loading Port: Shanghai Port or Ningbo Port

Features of Self-Clinching Nut

The key feature of a self clinching nut lies in its precision-designed undercut and clinching ring. This structure allows the surrounding sheet material to cold-flow into the nut during pressing, forming a secure mechanical lock without damaging the internal threads.

The flush-mounted design improves product appearance, while the hardened clinching area provides strong resistance to rotation. Self clinching nuts are suitable for both manual and automated installation, making them ideal for high-volume production lines.

Advantages of Self-Clinching Nut

Compared with weld nuts or tapped holes, self clinching nuts offer a more efficient and reliable fastening solution for thin sheet materials.

They eliminate heat distortion, reduce secondary processing steps, and provide reusable threads that maintain strength even after repeated assembly. Their consistent installation quality helps improve production efficiency and overall product reliability.

Installation Instructions for Self-Clinching Nut

Correct installation is critical to the performance of a self-clinching nut. The nut should be pressed into the sheet using a flat punch and solid anvil, ensuring the force is applied perpendicular to the sheet surface.

Material compatibility guidelines:

- Carbon steel self-clinching nuts: suitable for aluminum and steel plates with hardness HRB ≤ 80

- Stainless steel self-clinching nuts: suitable for aluminum and steel plates with hardness HRB ≤ 70

- Hardened stainless steel self-clinching nuts: suitable for stainless steel plates with hardness HRB ≤ 90

Using the correct nut material and plate hardness ensures proper metal flow and prevents installation failure.

Application of Self-Clinching Nut

Self-clinching nuts are widely used in applications that require strong internal threads in thin sheet metal structures. Common applications include electrical enclosures, control panels, automotive sheet metal parts, communication equipment, HVAC systems, office equipment, and industrial machinery housings.

They are especially suitable for designs requiring compact structures, clean surface finishes, and high vibration resistance.

Why Choose Xinchi Fastener Factory

Founded in 2007, Xinchi Fastener Factory is a professional manufacturer specializing in cold-forged fasteners, including Self Clinching Nuts. The factory operates 102 cold heading machines with a daily production capacity exceeding 10 million pieces, ensuring a stable supply for large-volume orders.

The newly completed production base covers 30,000 square meters, with two six-story factory buildings, advanced manufacturing equipment, and strict quality control systems. Xinchi supports both standard and customized self-clinching nut solutions, providing reliable quality, competitive pricing, and on-time delivery for global B2B customers.