Influence Of Wheel Nut Surface Treatment On Preload

Wheel connection pair is a very important part of vehicle application, its role is to connect the wheel and hub reliably together, so as to ensure the safety of the vehicle. The failure of the wheel connection pair will lead to serious consequences, not only will cause damage to vehicle parts but also may cause significant economic losses and casualties.

The failure form of the wheel connection pair is mainly the loosening of the connection pair, the fracture of the bolt, and then the direct result is that the wheel flies out and causes the accident. Through the analysis of the failure of the wheel bolt several times, it is found that the loosening of the bolt pair before fracture causes the decline of preload force, causing the relative movement between wheel and hub, making the bolt subject to the shear force of wheel mounting hole, leading to fatigue fracture. So stable preload is an important factor to ensure normal wheel connection.

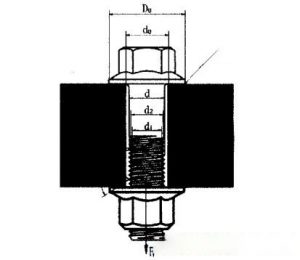

Wheel fastening in Chinese truck enterprises is mostly tightened by means of fixed torque by an automatic tightening machine. According to the detection of wheel bolts and nuts in China, the friction coefficient of wheel connectors of different manufacturers and different surface treatments is quite different. If the fixed torque method is used to tighten, there will be a large difference in the preloading force, and then affect the fastening performance of the wheel.

As a professional fastener company, Xinchi Fastener Company has many years of experience in the fastener field. Next, we are happy to share with you the effects of different surface treatments on the friction coefficient of wheel nuts, hoping to improve the reliability of wheel fastening.

- Through the analysis and calculation of wheel bolt torque and preloading force, it is concluded that the preloading force depends on the friction coefficient of the thread surface and the friction coefficient of the contact surface, and the slight change of friction coefficient has a great influence on the preloading force.

- Through the measurement of the friction coefficient, it is found that the friction coefficient of the contact surface of the wheel connecting pair is much larger than that of the thread, and the friction coefficient of the contact surface has a great influence on the comprehensive friction coefficient.

- It can be seen from the test data that white zinc plating and yellow zinc plating have little influence on the friction coefficient of the contact surface, thread friction coefficient, and comprehensive friction coefficient. Without the addition of friction coefficient sealer, the friction coefficient of the thread is relatively stable, indicating that the thread processing and surface treatment technology of this batch of nuts is consistent. However, the friction coefficient of the contact surface fluctuates greatly, which indicates that the stability of the friction coefficient of the contact surface, especially between the nut and the anti-loosening gasket, is very poor. The friction coefficient of the contact surface of the phosphating nut is very stable because of the rust-prevention oil.

- Through the test of wheel nuts with different surface treatments under normal supply conditions, it is concluded that the nuts with phosphating treatment can provide a very stable comprehensive friction coefficient without the use of friction coefficient sealer. That is, it can provide stable and controllable preloading force to ensure the reliable connection of the connection pair.

Xinchi Fastener Company is a trustworthy fastener company, especially in furniture nuts. And we are the designated fastener supplier to“STAPLE”. As a trusted fastener supplier, Xinchi Fastener Company can offer a wide range of high-quality fasteners, including tee nuts, screws, bolts, rivets, washers, etc. If you want to know more about fasteners or want to wholesale fasteners, please feel free to contact us. And then our experienced and expert service team will reply to you as soon as possible.