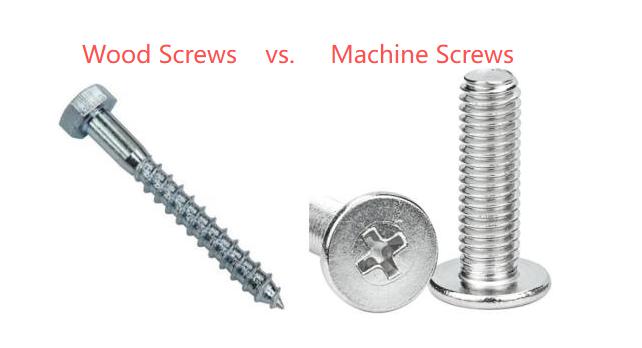

Wood Screws vs Machine Screws: Key Differences

When choosing fasteners, many buyers often wonder about the difference between wood screws and machine screws. Although both are commonly used, their design, application, and installation methods differ significantly.

As a professional fastener supplier, XINCHI is pleased to introduce these distinctions that can help you select the right screw for your project.

Thread Design of Wood Screws vs Machine Screws

The thread design is the most visible difference. Wood screws feature coarse, widely spaced threads with a sharp point, making it easy to penetrate and grip into wood fibers. In contrast, machine screws have fine, closely spaced threads that match standardized dimensions (metric or inch). Machine screws are designed to work with nuts or tapped holes rather than cutting into the material themselves.

Applications of Wood Screws vs Machine Screws

Wood screws are primarily used in woodworking projects, including furniture assembly, wooden frames, cabinets, and plywood fixtures. They are ideal for softwood and hardwood structures where strong holding power in wood fibers is needed.

On the other hand, machine screws are used in machinery, automotive components, metal parts, and plastic fittings with threaded inserts. They ensure secure connections in precision engineering and heavy-duty equipment.

Installation of Wood Screws vs Machine Screws

When installing wood screws, a pilot hole may be drilled, especially in hardwood, but in softer woods, they can often be driven directly using a screwdriver or power drill. Their sharp tip makes self-tapping easy.

In contrast, machine screws require a pre-threaded hole or a matching nut. They cannot cut their own threads and therefore depend on precise alignment with the mating thread for proper fastening.

Head Types of Wood Screws vs Machine Screws

Both screw types come in various head styles. Wood screws are often available in countersunk flat heads, pan heads, and oval heads, providing a clean and flush finish for furniture or wood panels.

Machine screws, however, include a wider variety, such as hex heads, socket heads, round heads, and flat heads, designed for mechanical strength and compatibility with washers.

Why Choose Xinchi Fasteners for Wood Screws and Machine Screws?

At Xinchi Fasteners, we specialize in manufacturing both wood screws and machine screws with strict quality standards. With over 102 cold-heading machines and a daily output of more than 10 million pieces, we ensure a stable supply and bulk order capacity. Our factory supports customization in size, material, and surface treatment, making us a trusted partner for global furniture producers, construction companies, and machinery manufacturers.

The key difference is simple: wood screws are self-tapping fasteners for wooden materials, while machine screws are precision fasteners requiring nuts or threaded holes in metal or plastic parts. Choosing the correct type ensures both efficiency and long-lasting performance.

XINCHI is a trustworthy fastener company, especially in furniture nuts. We have a factory, founded in 2007. We are the designated fastener supplier to“STAPLE”. As a trusted fastener supplier, XINCHI offers a wide range of high-quality fasteners, including nuts, screws, bolts, rivets, and washers. If you would like to learn more about fasteners or are interested in wholesale fasteners, please do not hesitate to contact us. Our experienced and expert service team will reply as soon as possible.