Rivet Nut Selection Guide: How to Choose the Right Blind Nut for Your Project

Rivet nuts, also known as blind nuts or threaded inserts, are versatile fasteners widely used for single-sided installation in thin metal, plastic, or ceramic panels. They provide strong, reliable threads without needing access to the backside of the workpiece, making them ideal for automotive, machinery, furniture, and electronic applications. Choosing the right rivet nut ensures stable connections, longer service life, and efficient assembly.

As a professional rivet nut manufacturer, Xinchi is glad to introduce how to choose the right blind nut for your project.

Technical Features of Rivet Nuts

Rivet nuts offer significant advantages over traditional fastening methods. They can be installed quickly—often in just a few seconds—without any surface finishing. Their dual function as both a rivet and a nut allows for secure connections in virtually any material, including metals, plastics, and ceramics. They are easy to operate, safe, eco-friendly, and provide cost-effective solutions for mass production or small-scale assembly.

Rivet Nut Application Range

When selecting a rivet nut, it is critical to ensure the thickness of the workpiece falls within the product’s recommended minimum and maximum range. Installing a rivet nut in material that is too thin or too thick can compromise its strength and lead to connection failure. Always verify the panel thickness and hole size before installation to achieve the best results.

Material Options for Rivet Nuts

Rivet nuts are available in a variety of materials to suit different applications:

- Carbon Steel: High strength and cost-effective, suitable for most industrial applications

- Stainless Steel: Corrosion-resistant, ideal for outdoor or humid environments

- Aluminum: Lightweight and corrosion-resistant, perfect for soft materials or lightweight assemblies

Selecting the right material ensures durability, corrosion resistance, and reliable performance.

Structure of Rivet Nuts

A rivet nut consists of three main parts, each influencing its performance:

- Head: The part that contacts the workpiece surface, affecting the stability and gap between components.

- Body: Connects the head and tail, contributing to anti-rotation properties and secure deformation during installation.

- Tail: Comes in open (through-hole) or closed (blind-hole) types, affecting screw length options and sealing performance.

Head Type Selection of Rivet Nuts

The head design impacts how the rivet nut interacts with the workpiece:

Flat Head: The most common industrial type; allows the rivet nut to sit flush with the surface, minimizing gaps.

Reduce Head: Reduces or eliminates the gap between parts, suitable for ductile materials where the gap can be absorbed. Not suitable for oversized holes or very soft, thin panels.

Countersunk Head: Requires a matching countersink in the workpiece; ideal for eliminating gaps when small countersunk heads cannot be used. The countersink depth should be slightly less than the head thickness for maximum contact and strength.

Body Shape Options of Rivet Nuts

The body design affects anti-rotation and stability:

Hexagonal Body: Provides the best anti-rotation performance when paired with a hex-shaped hole. Available as full or half hex shapes; performance is the same.

Round Body (Smooth or Knurled): Suitable where hexagonal holes cannot be made or in soft materials like aluminum and plastics. Knurled bodies improve anti-rotation performance.

Tail Type Options of Rivet Nuts

Closed-End(Blind-Hole): Provides sealing capabilities; some designs include grooves for O-rings to improve leak resistance.

Open-End(Through-Hole): Most common, allows flexibility in screw length, suitable for most panel applications.

Installation Guidelines of Rivet Nuts

Before installation:

- Check the hole shape and diameter according to the rivet nut product specification.

- Prefer hex or knurled rivet nuts for enhanced anti-rotation.

- Ensure workpieces are aligned and gaps are within acceptable limits.

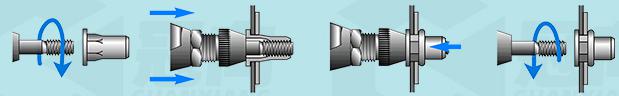

Installation method: “Rotate → Pull → Rotate” technique. The rivet nut is threaded onto the mandrel, inserted into the hole, then pulled without rotation to deform and secure the nut. Finally, the mandrel is removed. This ensures quick, reliable installation with strong holding power.

Xinchi Fasteners Factory Advantages

Anji Xinchi Fastening Piece Co., Ltd is a professional manufacturer of rivet nuts and other fasteners, offering:

- High-quality materials: Carbon steel, stainless steel, and aluminum for strength and corrosion resistance

- Precision manufacturing: Advanced CNC and cold forging processes for consistent dimensions and quality

- Large production capacity: 102 cold forging machines with over 10 million units daily

- Modern facilities: 30,000 m² factory with two six-story buildings for production and storage

- Wide product range: Rivet nuts, bolts, nuts, T-nuts, screws, washers, and more

- Custom solutions: Products can be manufactured to customer specifications

- Reliable service: Professional support, timely delivery, and strict quality control

Xinchi is a trustworthy fastener company, especially in furniture nuts. We have a factory, founded in 2007. We are the designated fastener supplier to“STAPLE”. As a trusted fastener supplier, XINCHI offers a wide range of high-quality fasteners, including nuts, screws, bolts, rivets, and washers. Xinchi Fasteners provides a one-stop solution for industrial and furniture fastening needs, trusted by clients worldwide.

If you would like to learn more about fasteners or are interested in wholesale fasteners, please do not hesitate to contact us. Our experienced and expert service team will reply as soon as possible.