Carbon Steel vs Stainless Steel Flange Bolts: Which Is Better?

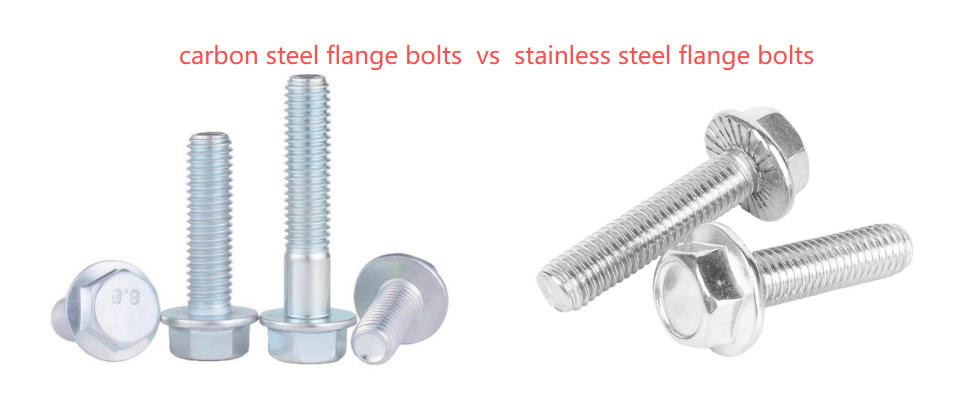

Flange bolts are widely used in machinery, construction, automotive, and structural assemblies thanks to their built-in washer design, which helps distribute load and reduce loosening. When buyers search for fastening solutions, carbon steel flange bolts and stainless steel flange bolts are two of the most commonly compared options.

As a professional fastener manufacturer, Xinchi is pleased to share the differences between carbon steel flange bolts and stainless steel flange bolts, with the hope that it will help engineers, purchasers, and project managers select the right flange bolts for their specific application environments.

What Are Flange Bolts and Why Material Matters

Flange bolts are fasteners with an integrated flange under the bolt head, acting as a washer to improve load distribution and enhance joint stability. The performance of a flange bolt is strongly influenced by its material, which affects strength, corrosion resistance, service life, and cost.

When comparing carbon steel vs stainless steel flange bolts, material choice directly determines whether the fastener is better suited for heavy-duty mechanical loads or corrosive operating environments.

Carbon Steel Flange Bolts: High Strength and Cost Efficiency

Carbon steel flange bolts are widely used in industrial applications where strength and affordability are key requirements. These flange bolts are typically manufactured from medium or high carbon steel and can be heat-treated to achieve higher tensile strength.

In machinery, structural steel connections, and automotive assemblies, carbon steel flange bolts provide excellent load-bearing capacity and resistance to vibration. To enhance corrosion resistance, surface finishes such as zinc plating, black oxide, or Dacromet are commonly applied. While carbon steel flange bolts require protective coatings, their strong mechanical performance and lower cost make them a practical choice for controlled or indoor environments.

Stainless Steel Flange Bolts: Corrosion Resistance and Stability

Stainless steel flange bolts are preferred in applications where corrosion resistance is critical. Made from grades such as A2 (304) or A4 (316), these flange bolts perform well in humid, outdoor, marine, and chemical environments.

Unlike carbon steel flange bolts, stainless steel flange bolts rely on their material composition rather than surface coatings to resist rust. They maintain a clean appearance and stable performance over long service periods. However, stainless steel flange bolts typically offer lower tensile strength compared to heat-treated carbon steel options, which should be considered when a high clamping force is required.

Carbon Steel vs Stainless Steel Flange Bolts: Key Performance Differences

When comparing carbon steel vs stainless steel flange bolts, the primary differences appear in strength, corrosion resistance, and application suitability.

Carbon steel flange bolts excel in high-load and high-stress environments, while stainless steel flange bolts are better suited for corrosive conditions. Choosing the correct flange bolt material depends on whether mechanical strength or environmental resistance is the priority in a given project.

Flange Bolt Selection Based on Application Environment

Selecting the right flange bolts requires a clear understanding of the operating environment. Carbon steel flange bolts are commonly used in dry indoor spaces, heavy equipment, and structural frameworks where corrosion exposure is limited.

Stainless steel flange bolts are often chosen for outdoor installations, coastal areas, food-processing equipment, and chemical plants. In these scenarios, corrosion resistance helps maintain fastening reliability and reduces maintenance over time.

Cost Considerations for Flange Bolts in Long-Term Use

From a budget perspective, carbon steel flange bolts generally offer a lower initial cost, making them suitable for large-volume industrial projects. Stainless steel flange bolts involve higher material costs but may provide better long-term value in corrosive environments by reducing replacement and maintenance expenses.

A lifecycle-based approach to flange bolt selection often helps balance upfront cost and long-term performance.

Which Flange Bolts Are Better?

There is no universal answer when comparing carbon steel vs stainless steel flange bolts. Each type of flange bolt serves a distinct purpose depending on load requirements, environmental conditions, and cost expectations.

Carbon steel flange bolts are ideal for strength-driven applications, while stainless steel flange bolts offer superior corrosion resistance in challenging environments. Understanding these differences allows buyers to make informed fastening decisions based on real-world usage rather than material preference alone.

About Xinchi Fasteners

Xinchi Fasteners is a professional manufacturer of industrial fasteners, including a full range of flange bolts in carbon steel and stainless steel materials. We have a factory that was founded in 2007.

- Large-scale production capacity: 102 cold-heading machines with a daily output of over 10 million pieces

- Modern facilities: New factory covering 30,000 square meters, two buildings with six floors each

- Strict quality control: Ensuring stable performance from raw materials to finished products

- Flexible customization: Different lengths, diameters, and thread specifications available

- Direct factory supply: Transparent pricing without middlemen

- Professional support: Fast response for bulk orders, distributors, and project sourcing

We are the designated fastener supplier to“STAPLE”. As a trusted fastener supplier, Xinchi offers a wide range of high-quality fasteners, including nuts, screws, bolts, rivets, and washers. Our products are widely used in automotive, machinery, construction, electronics, and furniture industries, trusted by global customers for stability, precision, and durability.

With advanced cold heading equipment, stable production capacity, and strict quality control, Xinchi supplies reliable fastening solutions for global customers across multiple industries.