Factors Of Hydrogen Embrittlement Fracture Of Alloy Steel Bolts

An alloy steel bolt is a metal-tight connection. Metal fastening bolts are widely used. Many large mechanical connectors will use metal fastening bolts to connect, such as alloy steel bolts. However, there is a common problem in the use of fastener bolts, that is, hydrogen embrittlement fracture. As long as the bolt has a little break, it will directly affect the normal use of machinery. For production machinery, sudden hydrogen embrittlement fracture of bolts will cause some losses. According to the analysis, Xinchi Fastener Company shares the specific factors and preventive measures for hydrogen embrittlement fracture of fastener bolts based on alloy steel.

Observation on fracture morphology of alloy steel bolts

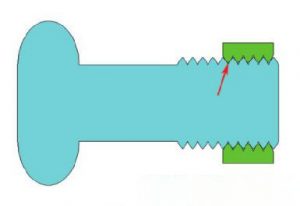

The diagram of the broken alloy steel bolt is shown below. The arrow points to the position where the bolt breaks. It can be seen that the fracture is at the point where the nut and thread are mechanically occluded.

The following figure shows the cross-section morphology of the bolt section under an electron microscope. As can be seen from the figure below, the section of the fracture and the axis of the bolt are 90°, and no trace of plastic deformation is observed from the section morphology. From the color of the fracture of the metal fastening bolt, the fracture is mainly silver gray, and the existence of an oxide doped in the silver-gray section can be observed.

If the metal fastening bolt has a hydrogen embrittlement fracture, it cannot be repaired and can only be replaced with a new one. Hydrogen embrittlement can only be prevented, but not eliminated. Because once hydrogen embrittlement occurs, it cannot be eliminated. In the smelting process of materials and the manufacturing and assembly process of parts (such as electroplating, and welding), the trace hydrogen (10 to minus 6 orders of magnitude) into the steel will lead to the embrittlement and even cracking of materials under the action of internal residual or external stress.

Causes of hydrogen embrittlement fracture of alloy steel bolts

Hydrogen is introduced from the external environment. When metal fastening bolts are exposed to a wet service environment for a long time, some hydrogen will seep in, or when they are served in areas with more rain, a higher proportion of metal fastening bolts will break due to hydrogen embrittlement.

Hydrogen is introduced during pickling. Alloy steel metal fastening bolts need to go through the process of pickling and electroplating, in which hydrogen atoms are easily introduced. Through the repeated study of the pickling process of alloy steel gold metal fastening bolts, it can be seen that hydrogen may be introduced into the process of phosphorylation and saponification of pickling. Especially in the phosphating process, under the action of phosphoric acid, iron, Fe and C form numerous galvanic cells, forming a phosphating film on the surface of the workpiece in the anode region, and releasing a large amount of hydrogen in the cathode region. Therefore, hydrogen absorption in the machining process should be the main source of hydrogen for broken bolts.

The smelting process does not completely remove hydrogen. It is unavoidable that some hydrogen atoms remain in alloy steel metal fastening bolts during smelting, which is closely related to temperature, environmental conditions and smelting process control. If there are some residual hydrogen atoms in the melting process of metal fastening bolts, these residual hydrogen atoms will promote the fracture process of alloy steel metal fastening bolts during the generation of hydrogen brittleness.

The fracture of an alloy steel bolt is a hydrogen-delayed brittle fracture, which is caused by the combined action of stress and hydrogen. The prevention of hydrogen embrittlement fracture of alloy steel bolts should be considered comprehensively according to the mechanism of hydrogen embrittlement fracture. According to the different tensile strengths required, select appropriate materials and reasonable processing technology (including heat treatment process, electroplating process, and pickling process), and take strict preventive measures.

Xinchi Fastener Company is a trustworthy fastener company, especially in furniture nuts. And we are the designated fastener supplier to“STAPLE”. As a trusted fastener supplier, Xinchi Fastener Company can offer a wide range of high-quality fasteners, including tee nuts, screws, bolts, rivets, washers, etc. If you want to know more about fasteners or want to wholesale fasteners, please feel free to contact us. And then our experienced and expert service team will reply to you as soon as possible.