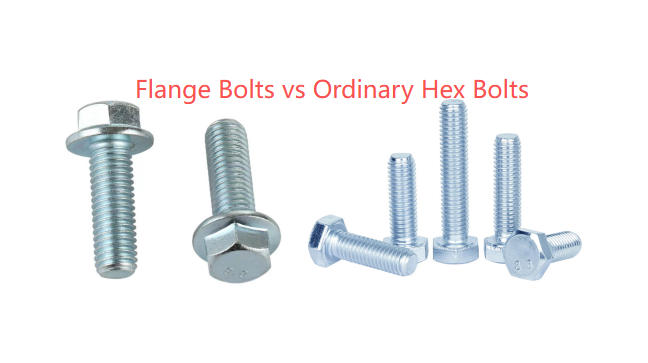

Flange Bolts vs Ordinary Hex Bolts

Flange bolts are common fasteners widely used across many industries. Ordinary bolts, often standard hex bolts, are even more common. Many people wonder what makes flange bolts different from ordinary hex bolts. As a professional fastener manufacturer, Xinchi Fasteners Factory is happy to explain.

Structure and Applications of Flange Bolts

Flange bolts consist of three main parts: a hex head, a flange (integrated under the hex head), and a threaded shank. They are mainly used to fasten two components with through-holes. The flange increases the contact area and distributes pressure evenly, providing better anti-slip performance. This makes flange bolts ideal for high-load or vibration-prone applications such as bridges, heavy machinery, industrial equipment, and civil construction.

Structure and Applications of Ordinary (Hex) Bolts

Ordinary bolts (standard hex bolts) have a simpler design: a hex head and a threaded shank without a flange. They are suitable for general fastening applications and usually have lower strength grades (e.g., grade 4.8). To improve fastening or anti-slip performance, washers or spring washers are typically used. This clarification ensures readers understand that ordinary bolts here refer specifically to external hex bolts.

Differences Between Flange Nuts and Ordinary Nuts

Flange nuts (also called washer nuts or serrated nuts) are usually paired with flange bolts and are used when increased contact area or anti-slip performance is needed, such as in pipe connections. The serrated surface increases contact with the workpiece, enhancing fastening strength. Ordinary nuts, in contrast, lack a flange and serrations, making them suitable only for lower-load applications.

Flange Bolts vs Ordinary (Hex) Bolts

Flange bolts: Hex head + flange, high load capacity, better anti-slip performance.

Ordinary bolts (hex bolts): Hex head only, lower load capacity, simple and economical.

Choosing between flange bolts and ordinary (hex) bolts depends on the specific application and load requirements.

Xinchi Fasteners Factory Advantages

Xinchi Fastener Factory has many years of experience and possesses numerous advantages.

- High-Quality Materials: Premium steel and alloys ensure strength, durability, and corrosion resistance.

- Precision Manufacturing: Advanced CNC and thread rolling processes guarantee consistent quality and precise dimensions.

- Extensive Production Capacity: The factory has 102 cold forging machines, with a daily output exceeding 10 million pieces.

- Modern Facilities: The new factory covers 30,000 m² with two six-story buildings, providing ample space for production and storage.

- Wide Product Range: Flange bolts, hex bolts, nuts, and other fasteners for industrial, construction, and mechanical applications.

- Custom Solutions: Production according to customer specifications and standards.

- Reliable Service: Professional support, timely delivery, and strict quality control make Xinchi a trusted partner.

Xinchi is a trustworthy fastener company, especially in furniture nuts. We have a factory, founded in 2007. We are the designated fastener supplier to“STAPLE”. As a trusted fastener supplier, Xinchi offers a wide range of high-quality fasteners, including nuts, screws, bolts, rivets, and washers. If you would like to learn more about fasteners or are interested in wholesale fasteners, please do not hesitate to contact us. Our experienced and expert service team will reply as soon as possible.

With Xinchi Fasteners, you get high-strength, durable, and reliable fastening solutions for any project.