How To Protect The Fastener Corrosion Of Railway Vehicles?

In the previous article, we analyzed The Reasons For The Corrosion Of Railway Vehicle Fasteners, so how should we protect against the corrosion of railway vehicle fasteners? In this article, Xinchi Fastener Company will introduce the corrosion treatment and protection of railway vehicle fasteners.

The process of rust removal and rust prevention of fasteners can effectively prevent the corrosion of fasteners. (Neutral WD-40 cleaning agent can be used for rust removal and anti-rust wax can be applied.)

Rust prevention process of fasteners

① Clean the surface of fasteners ② Fastener rust removal (spraying WD-40) ③ Fastener rust prevention (coated with anticorrosive wax) ④ Use the anticorrosive wax to dry

Surface cleaning of fastener

Before construction, the area around the anti-rust treatment site should be protected to ensure that the anti-corrosion wax, cleaning agent, and rust inhibitor do not pollute the rubber parts, plastic parts, electrical parts and other parts. Before rust prevention, dust, rust, oil and other impurities must be thoroughly removed from the surface of fasteners.

Rust removal for fasteners (sprayed with WD-40)

After spraying WD-40 rust remover and cleaning agent, wait for 5-10 minutes according to the degree of rust, so that wd-40 rust remover is fully immersed. Wipe the rusty parts with a soft cloth. Do not use abrasive materials such as sandpaper to wipe the parts, so as to avoid secondary damage to the protective layer on the surface of the parts in the process of rust removal. Repeat this step for severe rust until the rust is cleaned up. After dusting, the fasteners with unclear anti-loosening marks should be re-coated with anti-loosening marks. Technical requirements: Rust removal must be thorough, there can be no residual rust. After rust removal, the fastener’s anti-loosening mark can be seen.

Fastener rust prevention

The viscosity of anticorrosive wax varies with temperature. The lower the temperature, the higher the viscosity; The higher the temperature, the lower the viscosity. If sometimes the temperature of the storage warehouse is too low to cause the viscosity of the anticorrosive wax to be too high for construction, the anticorrosive wax can be placed in the workshop for a period of time before use, but be careful not to put it near the high heat object.

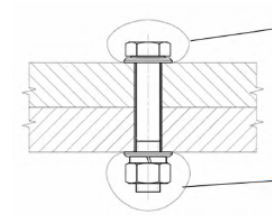

Figure 1 in above figure shows the specific positions for applying anti-corrosion wax to fasteners: bolt head, nut, gasket, cotter pin, positioning pin, etc. It is required that the anticorrosive wax cover the position above the fastener. The thickness of the anticorrosive wax coating is not required.

Figure 2 shows the application of antiseptic wax to special sites. For example, the carbon steel fasteners in the chute are coated with anticorrosive wax at one end of the chute before being put into the chute.

Note: Anti-corrosion wax and WD-40 contain combustible ingredients. Keep away from fire sources and hot objects during use and storage. Brush strokes can be used. No anti-corrosion wax is allowed outside 15mm of the plane around the fastener after brushing.

If there is a narrow gap next to some fasteners, the anti-corrosion wax will be spread into the gap during the coating process. In order to improve construction efficiency, a small amount of anti-corrosion wax is allowed in the narrow gap to ensure that the rubber parts, plastic parts, electrical parts and other parts are not polluted.

If some fasteners cannot be used with a brush and pen due to space limitations, you can use a cloth dipped in a little anti-corrosion wax daub.

Technical requirements: The anticorrosive wax coating should be done without leakage coating, ensuring that the entire fastener surface is covered with a layer of anticorrosive wax and the anti-loose mark can be visible. There are no specific requirements for the thickness of the anticorrosive wax coating.

Anticorrosive wax drying of fastener

Dry the fasteners at room temperature for at least 24 hours after application of anti-corrosion wax. Do not touch or scratch the surface of construction parts during the drying process to prevent damage to the coating protective film. If the anti-rust coating is damaged, repaint it according to the principle. After the completion of each process, the rust removal and rust prevention parts shall be self-inspected to check whether there is any missing coating part. If there is a missing coating, it shall be repaired in time.

Xinchi Fastener Company is a trustworthy fastener company, especially in furniture nuts. And we are the designated fastener supplier to“STAPLE”. As a trusted fastener supplier, Xinchi Fastener Company can offer a wide range of high-quality fasteners, including tee nuts, screws, bolts, rivets, washers, etc. If you want to know more about fasteners or want to wholesale fasteners, please feel free to contact us. And then our experienced and expert service team will reply to you as soon as possible.