Mistakes to Avoid When Installing Threaded Inserts

Threaded inserts are widely used to create strong and reusable threads in metal, wood, plastic, and composite materials. When installed correctly, threaded inserts significantly improve joint strength and service life. However, improper installation can easily lead to loose threads, reduced load capacity, or even part failure.

As a professional insert nut manufacturer, Xinchi is glad to introduce the most common installation mistakes, hoping it can help ensure threaded inserts perform as intended.

Threaded Inserts Mistake: Choosing the Wrong Insert Type

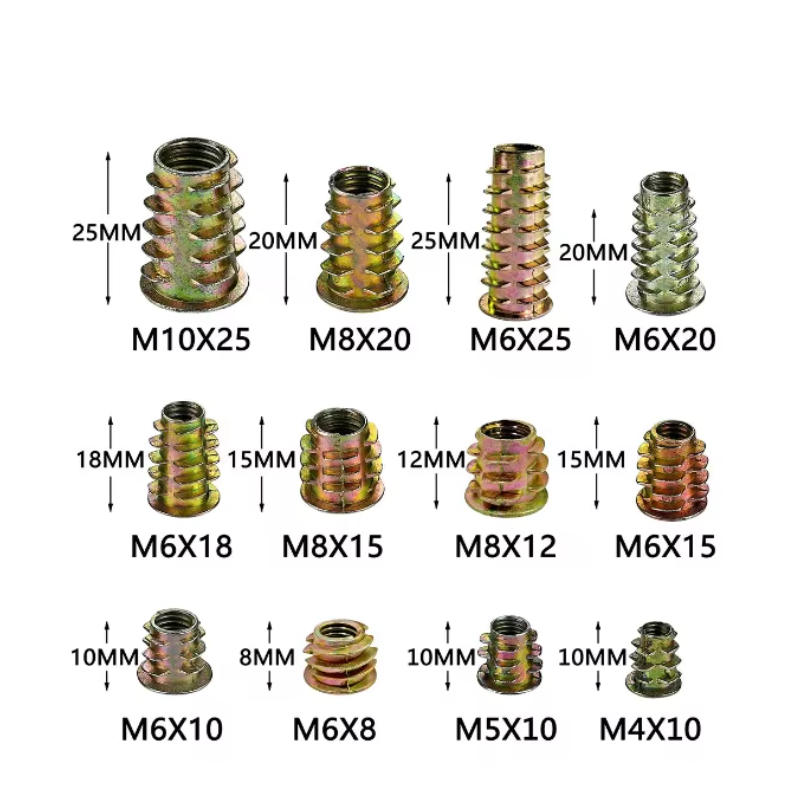

One of the most common problems when working with threaded inserts is selecting an insert that does not match the base material or application. Threaded inserts are designed differently for metal, wood, and plastic, and each type offers specific anchoring characteristics.

If the threaded insert material, structure, or thread profile is not suitable, it may fail to grip properly or loosen under load. Choosing the correct threaded inserts based on substrate material and load requirements is the foundation of a reliable installation.

Threaded Inserts Mistake: Incorrect Hole Size or Poor Alignment

Accurate hole preparation is critical for successful threaded insert installation. A hole that is too small can cause installation difficulty or damage the insert, while an oversized hole reduces holding strength and stability.

Equally important is alignment. If threaded inserts are installed at an angle, stress will not be evenly distributed along the threads. Proper drilling depth, diameter, and vertical alignment help threaded inserts seat correctly and maintain long-term performance.

Threaded Inserts Mistake: Installing Inserts in Dirty or Contaminated Holes

Another frequently overlooked issue is hole cleanliness. Dust, metal chips, oil, or residue left inside the hole can prevent threaded inserts from fully engaging with the base material.

Before installation, the hole should be cleaned thoroughly to ensure full contact between the threaded insert and the surrounding material. Clean installation conditions greatly improve the grip and reliability of threaded inserts.

Threaded Inserts Mistake: Over-Tightening or Under-Tightening During Installation

Applying the correct installation force is essential when setting threaded inserts. Over-tightening can deform the insert or damage the base material, while under-tightening may leave the insert loose and vulnerable to pull-out or rotation.

Following recommended torque values and using proper installation tools helps ensure threaded inserts are seated securely without compromising their structure or function.

Threaded Inserts Mistake: Using Low-Quality Inserts or Improper Tools

The quality of threaded inserts directly affects installation results and long-term durability. Low-quality inserts may have inconsistent threads, insufficient hardness, or poor surface treatment, increasing the risk of stripping or failure.

Using unsuitable or worn installation tools can also cause misalignment or thread damage. High-quality threaded inserts combined with correct tools help achieve stable, repeatable installation results.

Threaded Inserts Mistake: Ignoring Manufacturer Installation Guidelines

Each type of threaded insert comes with specific installation requirements, including hole size, installation method, and torque range. Ignoring these guidelines often leads to avoidable failures.

Following the manufacturer’s recommendations ensures threaded inserts achieve their designed holding strength and service life, especially in applications with vibration or repeated assembly.

Xinchi Advantages in Manufacturing Threaded Inserts

Xinchi Fasteners has specialized in manufacturing threaded inserts and other fasteners since 2007. Our factory operates 102 cold heading machines, with a daily output exceeding 10 million pieces, ensuring a stable supply for large-volume orders.

The newly completed factory covers 30,000 square meters, with two six-story production buildings, supporting efficient production, strict quality control, and consistent delivery. As a trusted fastener supplier, Xinchi offers a wide range of high-quality fasteners, including nuts, screws, bolts, rivets, and washers. Xinchi supplies threaded inserts that meet international standards, helping global customers achieve reliable fastening performance across various applications.