Some Common Cases Of Bolt Breakage

In the previous article, we introduced The Analysis Precautions Of Bolt Fracture. In this article, as a professional fastener company, we will continue to share some common cases of bolt breakage.

Case 1. Frequent breakage of connection bolts between the yaw bearing and base occurred on a project site, and oil seepage was found on the connection surface between the yaw bearing and base during the on-site inspection.

The cause of bolt breakage: when the unit is running, the stress amplitude of the bolt is too large, and the cross fastening of the bolt is not carried out according to the requirements when the bolt is replaced on-site, resulting in a gap between the flange faces.

Case 2: The bolts connecting the blades to the wheel hub frequently break at a project site, and signs of loosening of the bolts were found during the on-site inspection.

Causes of bolt breakage: When the unit is being repaired, the bolt is not tightened according to the requirements, resulting in bolt loosening; The wheel hub flange waist-type hole interferes with the bolt rod, and the torque value meets the requirement, but the bolt pre-tightening force is insufficient.

Case 3: The connection bolt between the blade and the propeller bearing is broken on a project site, and it is found that the screw in this position is fitted with the hole wall of the propeller bearing during the on-site inspection.

The cause of bolt breakage: the bolt is loose during installation or after operation of the unit, causing the bolt rod to fit with the hole wall of the variable propeller bearing, which causes the micro-vibration to wear fatigue fracture of the bolt.

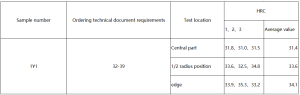

Case 4: The connection bolts between the rotor bearing and the wheel hub are broken multiple times on a project site, and the bolts are in the same batch.

Reasons for bolt breakage: the hardness of the broken bolt core is obviously low, which does not meet the technical requirements of the order; Under a metallography microscope, it was found that the heart was tempered shortening and a large amount of residual austenite, which belonged to the bolt quality problem.

Xinchi Fastener Company is a trustworthy fastener company, especially in furniture nuts. And we are the designated fastener supplier to“STAPLE”. As a trusted fastener supplier, Xinchi Fastener Company can offer a wide range of high-quality fasteners, including tee nuts, screws, bolts, rivets, washers, etc. If you want to know more about fasteners or want to wholesale fasteners, please feel free to contact us. And then our experienced and expert service team will reply to you as soon as possible.