The Comparison Of Several Lock Nuts For Vehicles

In the previous article, we introduced The Failure Analysis Of Ordinary Bolts And Nuts. As a professional fastener manufacturer, we Xinchi Fastener Company will continue to share The Comparison Of Several Lock Nuts For Vehicles in this article.

Ordinary hexagon bolts

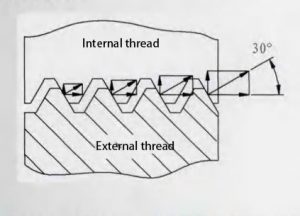

Ordinary hexagon bolts and nuts will still be the mainstream of automobile fasteners due to their large production batch, mature technology and low cost. Over the years, many fastener manufacturers have devoted themselves to the research of thread anti-loosening, and also made a special analysis on the loosening of ordinary hexagon bolts and nuts, focusing on the analysis of the factors affecting the preload of ordinary hexagon nuts in the manufacturing process. The main factors affecting the preloading force are tooth shape and friction coefficient. According to the preliminary analysis, for the common standard thread, most of the load is concentrated on the thread surface of the first and second teeth when the thread is occluded, with uneven distribution, and the friction coefficient is very discrete (see the following picture Ordinary Hexagon Bolt).

Users often have a misconception that more friction is better. In fact, the smaller the friction coefficient between the friction pair, the greater the axial clamping force, and the better the fastening performance. According to the theory that the influence of the change of friction coefficient on the tightening efficiency and tightness shows the trend of “scissors difference”, and verified by the test, the “median” friction coefficient is adopted, that is, the friction coefficient is smaller than that of the bolts and nuts in use, we call it the small friction coefficient. However, it is impossible to maintain a fixed value for all parts in mass production. Through the joint design of public relations with suppliers, we can improve the process and keep the friction coefficient in a reasonable range as far as possible.

Unloose nut

Many companies produce fasteners that claim to never loosen, such as DTFLOCK lock nut from the United States, HARDLOCK lock nut from Japan, DISC-LOCK lock washer from the United States, NORD-LOCK Lock lock washer from Sweden, etc. The DTFLOCK lock nut and the Japanese HARDLOCK lock nut were selected for comparison.

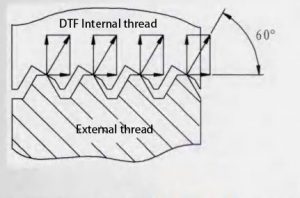

DTFLOCK nut

The DTFLOCK nut has a 30° wedge bevel at the tooth base of the internal thread. When the bolt and nut are tightened, the tooth tips of the bolt are pressed tightly against the wedge bevel of the nut, resulting in a great locking force. Because of the change in the Angle of the conodonts, the normal force exerted on the contacts between the threads is at a 60° Angle to the bolt shaft (see the following picture DTFLOCK Nut) instead of a 30° Angle as with normal threads. The normal pressure of the DTFLOCK thread is much greater than the fastening pressure, so the friction generated by the locking force must be greatly increased.

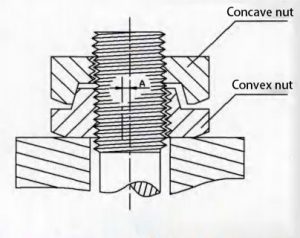

HARDLOCK nut

HARDLOCK nut is a double nut (see the following picture HARDLOCK Nut), and the outer side of the inner nut is provided with an eccentric protruding; The outer nut is of ordinary nut structure, and its inner side is provided with concentric grooves. When the outer nut is tight, the outer bulge of the inner nut is different from that of the bolt. The eccentric protrusion of the inner nut and the bolt are squeezed by the tightening of the outer nut to produce radial force, which is equivalent to increasing the wedge in the thread gap and locking the thread in all directions.

Xinchi Fastener Company is a trustworthy fastener company, especially in furniture nuts. And we are the designated fastener supplier to“STAPLE”. As a trusted fastener supplier, Xinchi Fastener Company can offer a wide range of high-quality fasteners, including tee nuts, screws, bolts, rivets, washers, etc. If you want to know more about fasteners or want to wholesale fasteners, please feel free to contact us. And then our experienced and expert service team will reply to you as soon as possible.